How Do Leveling Agents Affect the Surface Smoothness and Appearance of Coatings?

Introduction to Leveling Agents in Coatings

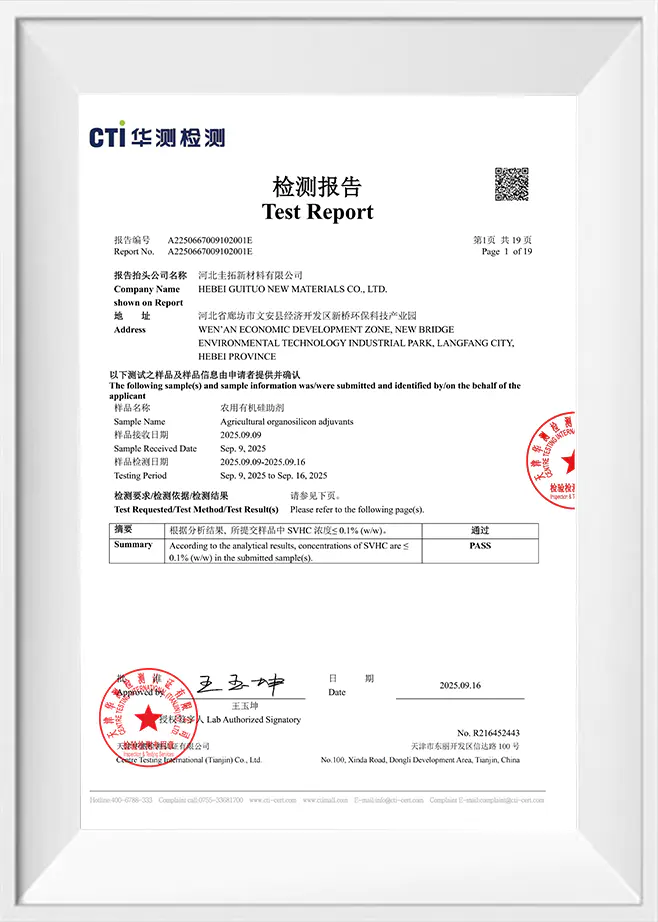

Leveling agents are additives used in coatings to improve surface smoothness and uniformity. These agents work by modifying the flow and spreading properties of the coating, ensuring that it levels out evenly on the substrate. The use of leveling agents is critical in various industries, including paints, coatings, and printing, where high-quality surface appearance is essential. Hebei Guituo New Material Co., Ltd. offers a range of silicone additives and surfactants, including leveling agents, that enhance the performance of coatings in different applications.

How Leveling Agents Function in Coatings

Leveling agents reduce the surface tension of the coating formulation, allowing it to flow more smoothly across the application surface. This reduction in surface tension prevents the formation of imperfections such as streaks, bubbles, and orange peel, which can occur when the coating fails to spread evenly. By promoting better wetting and spreading, leveling agents help achieve a smooth, uniform finish. Hebei Guituo New Material Co., Ltd. incorporates these agents into its product offerings, ensuring enhanced leveling properties in coatings for various industries, including agriculture, textiles, and daily chemicals.

Impact on Surface Smoothness

One of the primary benefits of using leveling agents is the improvement in surface smoothness. When applied, these agents help the coating to flow and spread evenly, eliminating surface defects such as brush marks or roller marks. This is particularly important in applications where a flawless finish is required, such as in high-end automotive coatings, furniture finishes, and electronics. Leveling agents ensure that the coating settles into a uniform layer, creating a smooth, visually appealing surface. Hebei Guituo New Material Co., Ltd.’s additives are designed to provide consistent and reliable surface smoothness, improving the overall appearance of coated products.

Appearance Enhancement

In addition to improving surface smoothness, leveling agents also contribute to the visual quality of coatings. The evenness of a coating directly affects its appearance, as uneven coatings can cause gloss inconsistencies and uneven color distribution. By ensuring an even layer of coating, leveling agents help achieve a uniform gloss level, enhancing the visual appeal of the final product. This is particularly important for products that require a high-quality aesthetic, such as consumer electronics or decorative coatings. Hebei Guituo New Material Co., Ltd. provides leveling agents that enhance not only the smoothness but also the overall appearance of coatings in various industries.

| Application Area |

Impact of Leveling Agents |

Key Benefits |

| Automotive Coatings |

Improved gloss uniformity and surface smoothness |

Enhanced visual appeal, consistent finish |

| Furniture Finishes |

Prevention of brush marks and roller marks |

Smoother appearance, better product quality |

| Textile Coatings |

Even coating distribution on fabric surfaces |

Improved aesthetics and functionality |

| Consumer Electronics |

Uniform gloss and consistent color appearance |

Enhanced product presentation and quality |

Viscosity and Leveling Agent Performance

The effectiveness of leveling agents can be influenced by the viscosity of the coating formulation. In high-viscosity coatings, the leveling agent needs to be carefully balanced to ensure that it does not cause excessive thinning or sagging. On the other hand, in low-viscosity formulations, leveling agents help to improve flow and prevent the formation of visible defects. Hebei Guituo New Material Co., Ltd. provides a range of silicone-based additives that are tailored to optimize performance in coatings with varying viscosities, ensuring smooth application and enhanced surface quality.

Factors Affecting the Efficiency of Leveling Agents

The performance of leveling agents can be affected by several factors, including temperature, humidity, and the substrate being coated. For instance, high humidity can slow the drying process, potentially interfering with the leveling effect and causing uneven surface textures. Similarly, very high or low temperatures can affect the viscosity of the coating and the behavior of the leveling agent. It is important to adjust the formulation of leveling agents to accommodate the environmental conditions and application method. Hebei Guituo New Material Co., Ltd. ensures that its leveling agents are formulated to perform consistently under a wide range of environmental conditions.

Compatibility with Other Coating Additives

Leveling agents must be compatible with other additives in the coating formulation, such as surfactants, thickeners, and defoamers. When combined, these additives must work synergistically to achieve the desired coating properties without causing incompatibility issues. For example, surfactants may affect the wetting properties, while thickeners can modify the viscosity, influencing the effectiveness of the leveling agent. Hebei Guituo New Material Co., Ltd. carefully formulates its additives to ensure compatibility, providing customers with reliable and efficient solutions for coating applications.

Long-Term Effects and Durability

The long-term performance of a coating is also influenced by the leveling agent used. In some cases, leveling agents may contribute to the durability of the coating by ensuring even film formation, which can reduce wear and tear over time. Moreover, a uniform surface reduces the chances of localized damage and helps maintain the appearance of the product for a longer period. Hebei Guituo New Material Co., Ltd. offers products designed to not only enhance the immediate visual quality of coatings but also to improve their long-term performance and durability.

FAQ

Q: What is a leveling agent and how does it work?

A: A leveling agent is an additive used in coatings to improve surface smoothness by reducing surface tension. It ensures that the coating flows evenly, eliminating imperfections like streaks, bubbles, or orange peel, and helps achieve a uniform finish.

Q: How do leveling agents affect the appearance of coatings?

A: Leveling agents help enhance the visual appeal of coatings by ensuring a consistent gloss level, smooth surface, and even color distribution. This results in a clean, flawless finish, particularly important in applications like automotive coatings and furniture finishes.

Q: What types of coatings benefit from the use of leveling agents?

A: Leveling agents are beneficial in a wide range of coatings, including those used in automotive, furniture, textiles, and electronics. They are particularly useful in coatings where high surface quality, smoothness, and uniformity are required.

Q: Can leveling agents improve the smoothness of coatings on uneven surfaces?

A: Yes, leveling agents can improve the spreadability and flow of coatings, helping to achieve a smoother, more even layer even on slightly uneven surfaces. This results in fewer surface defects and a more consistent appearance after application.

Q: Are leveling agents compatible with other coating additives?

A: Leveling agents are generally compatible with other additives such as surfactants, defoamers, and thickeners. However, it is essential to ensure proper formulation and compatibility to avoid issues such as instability or reduced performance. Hebei Guituo New Material Co., Ltd. designs its additives to ensure synergy with other coating components.

Q: How does the viscosity of a coating affect the performance of leveling agents?

A: The viscosity of the coating influences the effectiveness of leveling agents. In high-viscosity coatings, leveling agents must be carefully balanced to avoid causing thinning or sagging. In low-viscosity formulations, they help achieve better flow and prevent surface defects. Adjusting the formulation ensures optimal performance based on the desired viscosity.

Q: Can leveling agents impact the drying time of coatings?

A: Yes, leveling agents can affect the drying time of coatings. While they help improve flow and surface uniformity, they may slightly delay the curing process in some formulations. The drying time can be optimized by adjusting the concentration of the leveling agent and other components in the formulation.

English

English  Français

Français  Português

Português