Hebei Guituo New Materials Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales. As China Plastic Mold Release Agent Manufacturers and Industrial Rubber Mold Release Agent Suppliers, The company has always taken technology as the core driving force, focusing on the in-depth development and innovative application of high-end silicone materials in industrial and agricultural fields. It is a professional new materials enterprise with considerable influence in the industry. To ensure product quality and stable supply, the company has established a comprehensive guarantee system: it is equipped with internationally advanced production equipment and precise testing facilities, and has built a full-process quality monitoring mechanism from the production source to the delivery of finished products. It has assembled an experienced technical and production team with strong professional skills. With profound industry accumulation and precise technical control, it ensures that every product meets high standards.

In terms of product layout, the company has built a rich and diverse product matrix, covering silicone additives, wetting agents, modified silicone oil, dimethyl silicone oil, surfactants, defoamers, and other series, which are widely used in agriculture, daily chemicals, electronics, textiles, and other fields. Among them, the agricultural silicone products stand out for their outstanding quality, reaching an advanced domestic level. With excellent performance in multiple core indicators, they are favored by leading domestic agrochemical enterprises and have become their designated procurement products. At the same time, the company's products are exported to overseas markets such as Europe and Southeast Asia, winning wide recognition from overseas customers with stable performance and reliable quality, and achieving good market feedback through continuous repurchases. In addition, the company accepts OEM and ODM orders.

The Stability of Plastic Mold Release Agents Under Different Processing Temperatures and Environments

Overview of Plastic Mold Release Agents

Plastic mold release agents are functional materials applied to molds to reduce adhesion between the mold surface and the plastic product during processing. These agents are essential for improving production efficiency, reducing defects, and extending mold life. Hebei Guituo New Material Co., Ltd., with its diverse product matrix including silicone additives, dimethyl silicone oil, modified silicone oils, surfactants, and defoamers, supplies mold release agents that are formulated to maintain stability under various processing conditions.

Effect of High-Temperature Processing

High-temperature processing environments, such as injection molding and extrusion, can affect the chemical and physical stability of plastic mold release agents. At elevated temperatures, some release agents may degrade, lose viscosity, or evaporate, leading to reduced effectiveness and uneven mold coverage. Silicone-based release agents, such as those supplied by Hebei Guituo New Material Co., Ltd., offer high thermal stability due to the silicon-oxygen backbone, allowing them to maintain performance in high-temperature operations without compromising mold release efficiency.

Performance in Low-Temperature Processing

Low-temperature processing, such as cooling molds or cold extrusion, presents different challenges. Release agents must maintain uniform coverage without becoming too viscous or forming uneven films. Silicone oils with low viscosity and stable emulsified formulations can adapt to low-temperature conditions, ensuring consistent release behavior. Hebei Guituo New Material Co., Ltd.’s plastic mold release products are formulated to retain functional integrity across a range of low-temperature operations in both industrial and agricultural applications.

Environmental Factors Affecting Stability

Environmental factors such as humidity, exposure to air, and contact with other chemical agents can influence the stability of plastic mold release agents. Moisture can affect water-based formulations, causing phase separation or reduced wetting. In solvent-based systems, evaporation and chemical reactions may alter performance. Hebei Guituo New Material Co., Ltd. optimizes its formulations by balancing silicone oils, emulsifiers, and surfactants to ensure compatibility and maintain stability under varied environmental conditions.

Compatibility with Plastic Materials

The chemical nature of the plastic being processed can also impact the effectiveness of a mold release agent. Some plastics may interact with release agents, affecting spreading and adhesion prevention. Silicone-based release agents are generally compatible with a wide range of plastics, including polyethylene, polypropylene, PVC, and engineering plastics. The experience of Hebei Guituo New Material Co., Ltd. in providing silicone additives supports formulations that maintain stable release properties across different polymer types.

| Processing Condition | Potential Challenge | Release Agent Stability Consideration |

|---|---|---|

| High temperature | Thermal degradation, evaporation | Use thermally stable silicone-based formulations |

| Low temperature | Increased viscosity, uneven spreading | Employ low-viscosity emulsified oils for uniform coverage |

| High humidity | Phase separation, reduced wetting | Incorporate surfactants and stabilizers to maintain emulsion |

| Exposure to chemicals | Chemical reaction with other additives | Ensure chemical compatibility in formulation |

Impact on Mold Surface and Product Quality

Stable mold release agents contribute to consistent mold surface protection and improved product quality. Variations in stability may lead to residue buildup, surface defects, or incomplete demolding. Using silicone-based release agents with well-balanced emulsifiers and additives, as provided by Hebei Guituo New Material Co., Ltd., helps maintain smooth surfaces, reduce cycle times, and support repeatable production results.

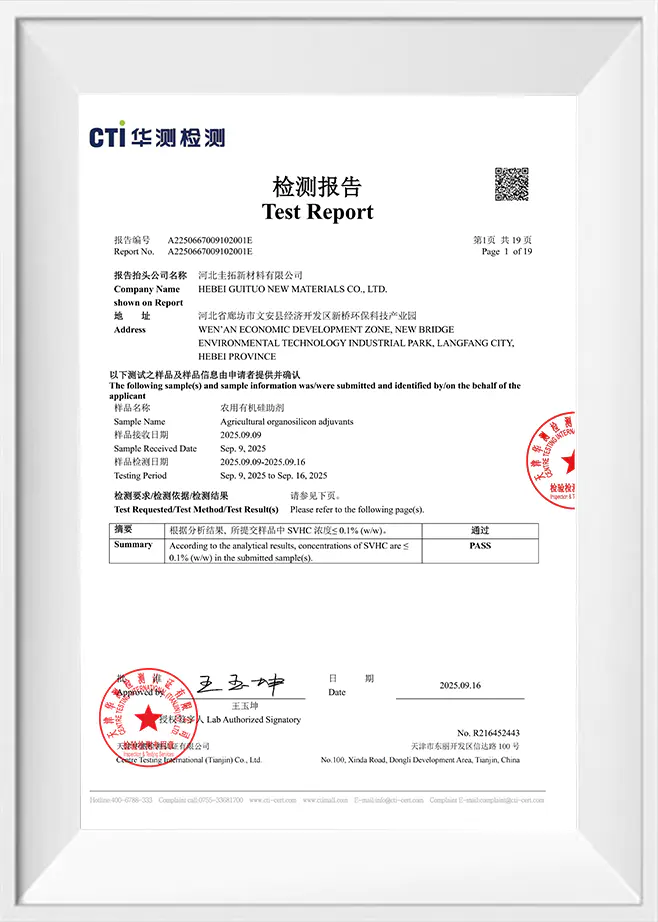

Evaluation Methods for Stability

Stability of plastic mold release agents can be evaluated by thermal aging tests, low-temperature storage tests, and chemical resistance assessments. Observing emulsion separation, viscosity changes, and surface wetting performance under simulated processing conditions provides insights into long-term reliability. Hebei Guituo New Material Co., Ltd. applies these evaluation methods during product development to ensure that its mold release agents perform consistently in diverse industrial applications.

Formulation Adjustments for Enhanced Stability

Adjustments in silicone oil viscosity, emulsifier selection, and additive concentration allow mold release agents to be tailored for specific processing environments. High-temperature processes may require more thermally robust silicone oils, while low-temperature applications benefit from lower-viscosity oils. By customizing formulations in this manner, Hebei Guituo New Material Co., Ltd. ensures that its mold release products maintain stability, efficiency, and compatibility with different plastics and environmental conditions.

Industrial Rubber Mold Release Agents: Compatibility with and Protection of Molds

Introduction to Rubber Mold Release Agents

Industrial rubber mold release agents are essential materials used to reduce friction between the mold surface and the rubber product during the molding process. These agents prevent sticking, ensuring smooth demolding and protecting molds from wear and damage. Hebei Guituo New Material Co., Ltd. offers a variety of release agents, including modified silicone oils and surfactants, which are designed to meet the needs of diverse industrial applications, including rubber molding.

Compatibility with Rubber Materials

The compatibility of mold release agents with different rubber materials is crucial for achieving effective release and preventing contamination. Rubber compounds, such as natural rubber, synthetic rubber, and elastomers, often have different chemical compositions and surface characteristics. Silicone-based release agents, such as those developed by Hebei Guituo New Material Co., Ltd., are widely compatible with various rubber types. These agents form a non-stick layer on the mold surface, which prevents the rubber from adhering to the mold while maintaining the integrity of the rubber product.

Protection of Molds from Corrosion and Wear

One of the key functions of mold release agents is to protect the mold from corrosion, abrasion, and surface damage during the molding process. Without a protective layer, continuous friction and exposure to harsh chemicals could lead to mold degradation, increasing maintenance costs and reducing mold lifespan. Silicone-based release agents offer effective mold protection by forming a durable barrier that prevents direct contact between the mold surface and the rubber compound. This protection helps maintain mold quality and extends its operational life, ensuring more cost-effective production. Hebei Guituo New Material Co., Ltd. focuses on providing release agents that not only improve release efficiency but also offer long-term protection against wear and tear.

Impact on Surface Finish and Product Quality

The choice of mold release agent directly impacts the surface finish and quality of the molded rubber products. Some release agents can leave residue or create surface defects that affect the final product’s appearance or performance. High-quality silicone-based release agents, like those supplied by Hebei Guituo New Material Co., Ltd., are formulated to leave minimal residue, ensuring that the molded rubber parts have a smooth, clean surface. These agents help maintain the desired surface characteristics, such as gloss, smoothness, and uniformity, without compromising the mechanical properties of the rubber.

| Rubber Type | Release Agent Compatibility | Key Benefits |

|---|---|---|

| Natural Rubber | Silicone-based release agents | Prevents adhesion, improves mold protection |

| Synthetic Rubber | Silicone and non-silicone agents | Enhanced mold release, consistent surface quality |

| Elastomers | Specialized silicone agents | Effective protection, easy demolding |

Temperature and Environmental Resistance

The effectiveness of industrial rubber mold release agents can be influenced by the temperature and environmental conditions during the molding process. High temperatures, in particular, can affect the stability of the release agent and lead to premature breakdown or volatilization. Silicone-based agents, such as those offered by Hebei Guituo New Material Co., Ltd., are known for their high-temperature stability, making them suitable for rubber molding processes that involve elevated temperatures. These agents maintain their protective and release properties even in challenging environments, ensuring consistent mold release and mold protection over extended production cycles.

Application of Mold Release Agents in Different Rubber Processing Methods

Different rubber molding methods, such as compression molding, injection molding, and transfer molding, require specific types of mold release agents. For example, in injection molding, where high pressures and temperatures are applied, release agents with excellent thermal stability and minimal residue are necessary to avoid clogging or damaging the mold. Hebei Guituo New Material Co., Ltd. supplies silicone-based release agents that are optimized for use in various molding techniques. These agents ensure that molds remain in excellent condition while providing efficient release for a wide range of rubber materials.

Environmental and Safety Considerations

In the selection of mold release agents, environmental impact and worker safety are important considerations. Silicone-based release agents are generally regarded as safe, non-toxic, and environmentally friendly, especially when compared to solvent-based alternatives. They do not release harmful volatile organic compounds (VOCs), contributing to a safer and more sustainable working environment. Hebei Guituo New Material Co., Ltd. ensures that its products meet industry safety standards, providing safe and effective solutions for industrial rubber molding applications.

Formulation Customization for Specific Needs

The performance of mold release agents can be tailored by adjusting their formulation to meet specific requirements. Factors such as the type of rubber, the molding temperature, and the complexity of the mold can all influence the ideal composition of the release agent. Hebei Guituo New Material Co., Ltd. offers customizable solutions to ensure optimal performance for different industrial applications. Whether for enhancing mold protection, improving product quality, or increasing production efficiency, these agents can be adjusted to suit the unique needs of each molding process.

English

English  Français

Français  Português

Português