Hebei Guituo New Materials Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales. As China Organosilicone Defoamer Manufacturers and Organosilicone Defoamer Suppliers, The company has always taken technology as the core driving force, focusing on the in-depth development and innovative application of high-end silicone materials in industrial and agricultural fields. It is a professional new materials enterprise with considerable influence in the industry. To ensure product quality and stable supply, the company has established a comprehensive guarantee system: it is equipped with internationally advanced production equipment and precise testing facilities, and has built a full-process quality monitoring mechanism from the production source to the delivery of finished products. It has assembled an experienced technical and production team with strong professional skills. With profound industry accumulation and precise technical control, it ensures that every product meets high standards.

In terms of product layout, the company has built a rich and diverse product matrix, covering silicone additives, wetting agents, modified silicone oil, dimethyl silicone oil, surfactants, defoamers, and other series, which are widely used in agriculture, daily chemicals, electronics, textiles, and other fields. Among them, the agricultural silicone products stand out for their outstanding quality, reaching an advanced domestic level. With excellent performance in multiple core indicators, they are favored by leading domestic agrochemical enterprises and have become their designated procurement products. At the same time, the company's products are exported to overseas markets such as Europe and Southeast Asia, winning wide recognition from overseas customers with stable performance and reliable quality, and achieving good market feedback through continuous repurchases. In addition, the company accepts OEM and ODM orders.

How Does Organosilicone Defoamer Perform in Terms of Compatibility in Different Systems?

Basic Composition and Functional Mechanism of Organosilicone Defoamers

Organosilicone defoamers are formulated based on silicone oils, modified silicone oils, and functional additives that work together to control foam formation. Their defoaming action relies on low surface tension and controlled spreading behavior, which allows them to disrupt foam films in liquid systems. Compatibility is a key performance factor because defoamers must function without negatively affecting the stability or appearance of the host formulation. Hebei Guituo New Material Co., Ltd., with its portfolio of silicone additives and surfactants, emphasizes balanced formulation design to support compatibility across multiple industrial systems.

Compatibility in Aqueous Systems

In water-based systems, organosilicone defoamers must disperse effectively without forming visible oil spots or causing separation. Compatibility in such systems is influenced by the choice of emulsifiers and wetting agents used in the defoamer formulation. In agriculture and daily chemical applications, where water is the primary medium, stable dispersion is essential for maintaining formulation clarity and uniformity. Hebei Guituo New Material Co., Ltd. integrates suitable surfactants into its silicone defoamer solutions to help achieve controlled dispersion and reduce the risk of instability during storage and use.

Behavior in High-Surfactant Formulations

High-surfactant systems, such as detergents and certain agrochemical formulations, present additional challenges for defoamer compatibility. Surfactants can reduce the effectiveness of defoamers by stabilizing foam films. Organosilicone defoamers with tailored molecular structures are often more compatible in these environments, as they can maintain defoaming activity without excessive interaction with the surfactant network. The experience of Hebei Guituo New Material Co., Ltd. in producing both surfactants and defoamers supports the optimization of compatibility in such complex systems.

| System Type | Compatibility Focus | Observed Behavior |

|---|---|---|

| Water-based formulations | Dispersion stability | Uniform distribution without separation |

| High-surfactant systems | Interaction balance | Maintained defoaming activity |

| Low-surfactant systems | Spreading control | Reduced surface defects |

Compatibility in Oil-Based and Solvent Systems

In oil-based or solvent-based systems, organosilicone defoamers must be compatible with nonpolar or semi-polar media. Modified silicone oils are often used to improve solubility and reduce the risk of phase separation. In electronics and textile processing, where solvent systems are common, compatibility ensures that the defoamer does not interfere with coating uniformity or surface properties. Hebei Guituo New Material Co., Ltd. utilizes its modified silicone oil technology to support compatibility in these environments.

Influence of Processing Conditions on Compatibility

Processing conditions such as temperature, shear force, and mixing sequence can significantly affect defoamer compatibility. High shear may lead to excessive dispersion, reducing defoaming efficiency, while insufficient mixing can cause localized concentration differences. Evaluating compatibility therefore involves observing defoamer behavior under simulated processing conditions. In agricultural silicone products, where large-scale mixing is common, controlling these variables helps ensure consistent defoaming performance throughout the production process.

Impact on Final Product Appearance and Stability

Compatibility is closely linked to the visual and physical stability of the final product. An incompatible defoamer may cause surface defects, haze, or sedimentation over time. Organosilicone defoamers that are well-matched to the system tend to remain inactive when foam is absent and activate only when foam forms. This selective behavior helps maintain formulation stability, which is particularly important in daily chemical and agrochemical products supplied by Hebei Guituo New Material Co., Ltd.

| Evaluation Aspect | Test Method | Compatibility Indicator |

|---|---|---|

| Visual stability | Storage observation | No oil spots or layering |

| Foam control persistence | Repeated agitation | Consistent foam suppression |

| Formulation integrity | Long-term storage test | Minimal change in properties |

Compatibility in Agricultural Formulations

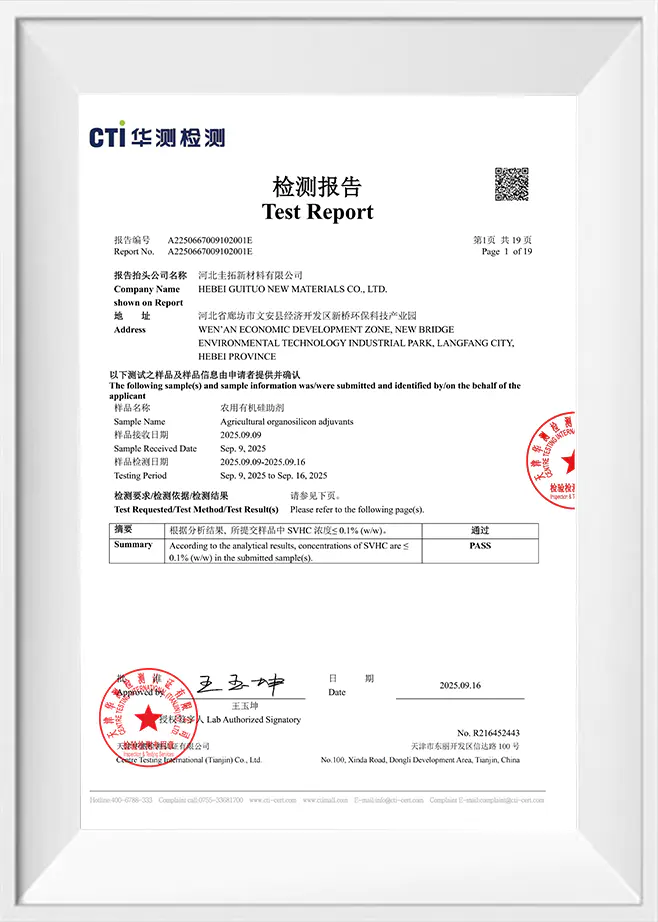

Agricultural formulations often contain active ingredients, dispersants, and wetting agents that can interact with defoamers. Compatibility in this context means that the defoamer should not reduce the effectiveness of active components or cause instability. Hebei Guituo New Material Co., Ltd.’s agricultural silicone products are widely used by domestic agrochemical enterprises, and compatibility testing is an important part of ensuring that organosilicone defoamers perform reliably within these multi-component systems.

Role of Customized Formulation in Improving Compatibility

Different application systems require different compatibility strategies. By adjusting silicone oil viscosity, modifying molecular structure, and selecting suitable surfactants, organosilicone defoamers can be tailored to specific system requirements. Hebei Guituo New Material Co., Ltd. applies this customization approach across its product matrix, supporting compatibility in agriculture, daily chemicals, electronics, and textile processing while maintaining stable defoaming behavior.

FAQ

Q: What is an organosilicone defoamer and what is its main function?

A: An organosilicone defoamer is a foam control agent formulated with silicone oil, modified silicone oil, and functional additives. Its main function is to reduce or suppress foam generated during production, mixing, or application processes, helping maintain stable processing conditions in various industrial systems.

Q: In which industries are organosilicone defoamers commonly used?

A: Organosilicone defoamers are widely used in agriculture, daily chemicals, electronics, textile processing, and other industrial fields. Hebei Guituo New Material Co., Ltd. supplies organosilicone defoamers that support these applications as part of its diversified silicone product matrix.

Q: Why are organosilicone defoamers suitable for agricultural formulations?

A: Agricultural formulations often involve high-speed mixing and complex surfactant systems that easily generate foam. Organosilicone defoamers provide effective foam control while maintaining compatibility with active ingredients, which supports stable formulation performance. Hebei Guituo New Material Co., Ltd.’s agricultural silicone products are widely adopted by domestic agrochemical enterprises for this reason.

Q: How does an organosilicone defoamer interact with surfactants and wetting agents?

A: Organosilicone defoamers are designed to work alongside surfactants and wetting agents without causing formulation instability. Proper balance between these components allows the defoamer to control foam while preserving dispersion and wetting performance, an approach supported by Hebei Guituo New Material Co., Ltd.’s integrated product portfolio.

Q: What factors affect the compatibility of an organosilicone defoamer?

A: Compatibility is influenced by factors such as system polarity, surfactant concentration, processing temperature, and mixing conditions. Modified silicone oils and suitable emulsification systems are often used to improve compatibility across different formulations.

Q: Can organosilicone defoamers be used in water-based systems?

A: Yes, many organosilicone defoamers are formulated for water-based systems. Through the use of appropriate surfactants and additives, they can disperse evenly in aqueous formulations and maintain stable foam control during storage and application.

Q: How does Hebei Guituo New Material Co., Ltd. support defoamer application needs?

A: Hebei Guituo New Material Co., Ltd. combines its experience in silicone additives, modified silicone oil, surfactants, and defoamers to support different application requirements. By aligning defoamer performance with specific industry systems, the company helps customers achieve stable processing and consistent product quality.

English

English  Français

Français  Português

Português