What Is Polyether-Modified Silicone Oil, and How Do Its Structural Characteristics Affect Its Performance?

Basic Concept of Polyether-Modified Silicone Oil

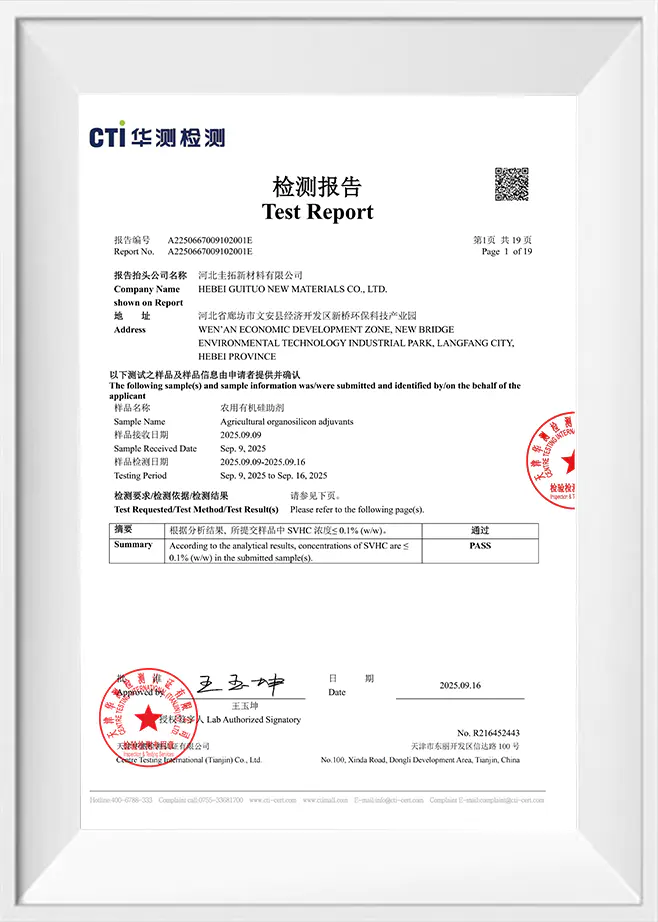

Polyether-modified silicone oil is a functional silicone material formed by introducing polyether chains into the backbone or side chains of silicone oil. This structural modification combines the flexibility and thermal stability of silicone with the polarity and hydrophilicity of polyether segments. As a result, the material shows behavior that differs from conventional dimethyl silicone oil. Hebei Guituo New Material Co., Ltd., with its product matrix covering modified silicone oil, surfactants, and silicone additives, applies this type of material across agriculture, daily chemicals, electronics, and textile processing.

Core Structural Elements and Their Roles

The performance of polyether-modified silicone oil is closely related to its molecular structure. The silicone backbone provides flexibility, low surface energy, and temperature resistance, while the polyether segments introduce polar groups that improve compatibility with water-based and polar systems. The length of the polyether chain, the ratio between silicone and polyether components, and the connection method between them all influence the balance between hydrophobic and hydrophilic behavior. These structural variables allow manufacturers to adjust the material for specific application needs.

Effect of Polyether Chain Length on Performance

Polyether chain length has a direct impact on solubility and interfacial behavior. Shorter polyether chains tend to maintain more silicone-like characteristics, such as lower surface tension and stronger spreading on nonpolar surfaces. Longer polyether chains increase water compatibility and dispersibility in aqueous systems. In agricultural formulations, where water-based systems are common, selecting an appropriate polyether chain length helps ensure stable dispersion without compromising functional performance. Hebei Guituo New Material Co., Ltd. considers this factor when aligning its modified silicone oil products with agrochemical requirements.

Influence of Silicone-to-Polyether Ratio

The ratio between silicone segments and polyether segments determines the overall balance of properties. A higher silicone content typically supports better surface activity and lubrication behavior, while a higher polyether content enhances emulsification and wetting in polar environments. This ratio affects how the material behaves as a wetting agent, defoamer component, or formulation modifier. By adjusting this structural parameter, polyether-modified silicone oil can be adapted for use in daily chemicals, electronics processing, and textile finishing.

| Structural Parameter |

Primary Influence |

Typical Application Focus |

| Short polyether chain |

Lower polarity, better spreading |

Surface treatment, lubrication |

| Long polyether chain |

Higher water compatibility |

Water-based formulations |

| High silicone ratio |

Surface activity |

Defoaming and release control |

| High polyether ratio |

Emulsification ability |

Wetting and dispersion |

Connection Mode and Molecular Architecture

Polyether-modified silicone oils can be designed with different connection modes, such as block or graft structures. Block structures often show clearer phase behavior between silicone and polyether segments, while graft structures tend to provide more uniform property distribution. These architectural differences influence viscosity, cloud point, and interaction with other formulation components. Hebei Guituo New Material Co., Ltd. evaluates these structural factors when supplying materials intended for complex multi-component systems.

Impact on Viscosity and Flow Behavior

Structural characteristics also affect viscosity and flow properties. Increasing polyether content generally raises viscosity and enhances interaction with polar components. This can improve formulation stability but may require processing adjustments. In contrast, silicone-rich structures often maintain lower viscosity and smoother flow. For processing environments such as electronics manufacturing or agricultural product blending, understanding this relationship helps optimize handling and application efficiency.

Performance in Wetting and Spreading Applications

One of the key functions of polyether-modified silicone oil is its role as a wetting agent. The polyether segments reduce interfacial tension between water and hydrophobic surfaces, while the silicone segments promote rapid spreading. This dual behavior supports uniform coverage on plant surfaces in agricultural applications and consistent coating in textile processing. Hebei Guituo New Material Co., Ltd. integrates this material into its wetting agent solutions to support stable and controlled performance.

Compatibility with Surfactants and Other Additives

Polyether-modified silicone oil often shows improved compatibility with nonionic and anionic surfactants compared to unmodified silicone oil. The presence of polyether chains reduces the risk of separation and supports more uniform formulations. This compatibility is important in systems that also contain defoamers, dispersants, and functional additives. Hebei Guituo New Material Co., Ltd. leverages this property to support integrated solutions across its silicone additives and surfactant product lines.

| Formulation Component |

Interaction Characteristic |

Practical Benefit |

| Nonionic surfactants |

Good mutual compatibility |

Stable dispersion |

| Anionic surfactants |

Improved tolerance |

Reduced separation risk |

| Silicone additives |

Structural synergy |

Balanced performance |

Application-Oriented Structural Adjustment

Different industries require different performance balances, which can be achieved through structural adjustment of polyether-modified silicone oil. In agriculture, emphasis is placed on water compatibility and spreading efficiency. In daily chemicals, mildness and formulation stability are important. Electronics and textile applications may focus on controlled wetting and surface behavior. Hebei Guituo New Material Co., Ltd. aligns structural design with these application requirements, supporting practical and reliable use across diverse fields.

FAQ

Q: How does polyether modification change the properties of silicone oil?

A: The introduction of polyether chains improves water compatibility, dispersion, and interaction with polar components. Compared with conventional dimethyl silicone oil, polyether-modified silicone oil shows improved wetting behavior and formulation adaptability in complex systems.

Q: In which industries is polyether-modified silicone oil commonly used?

A: Polyether-modified silicone oil is widely used in agriculture, daily chemicals, electronics, and textile processing. Hebei Guituo New Material Co., Ltd. supplies this material as part of its modified silicone oil series to support these diverse application areas.

Q: Why is polyether-modified silicone oil suitable for agricultural formulations?

A: Agricultural formulations are often water-based and require good spreading and compatibility with active ingredients. Polyether-modified silicone oil supports these requirements by improving wetting and dispersion, which helps maintain stable formulation performance in agrochemical applications.

Q: How does polyether-modified silicone oil function as a wetting agent?

A: The silicone segment reduces surface tension and promotes spreading, while the polyether segment enhances interaction with water and polar surfaces. This combined structure allows the material to act as an effective wetting agent in various formulations.

Q: Is polyether-modified silicone oil compatible with surfactants and defoamers?

A: Yes, polyether-modified silicone oil generally shows good compatibility with many nonionic and anionic surfactants, as well as silicone-based defoamers. This compatibility supports stable formulations in daily chemical and industrial systems.

Q: What factors should be considered when selecting polyether-modified silicone oil?

A: Selection factors include polyether chain length, silicone-to-polyether ratio, viscosity, and the target application environment. Hebei Guituo New Material Co., Ltd. aligns these parameters with customer requirements across agriculture, electronics, and textile processing.

English

English  Français

Français  Português

Português