As China Chemical Raw Materials Factory and Wholesale Organosilicon Raw Materials Manufacturers, Ningbo Guituo Trading Co., Ltd. is a subsidiary of Hebei Guituo New Materials Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales. The company has always taken technology as the core driving force, focusing on the in-depth development and innovative application of high-end silicone materials in industrial and agricultural fields. It is a professional new materials enterprise with considerable influence in the industry. To ensure product quality and stable supply, the company has established a comprehensive guarantee system: it is equipped with internationally advanced production equipment and precise testing facilities, and has built a full-process quality monitoring mechanism from the production source to the delivery of finished products. It has assembled an experienced technical and production team with strong professional skills. With profound industry accumulation and precise technical control, it ensures that every product meets high standards.

In terms of product layout, the company has built a rich and diverse product matrix, covering silicone additives, wetting agents, modified silicone oil, dimethyl silicone oil, surfactants, defoamers, and other series, which are widely used in agriculture, daily chemicals, electronics, textiles, and other fields. Among them, the agricultural silicone products stand out for their outstanding quality, reaching an advanced domestic level. With excellent performance in multiple core indicators, they are favored by leading domestic agrochemical enterprises and have become their designated procurement products. At the same time, the company's products are exported to overseas markets such as Europe and Southeast Asia, winning wide recognition from overseas customers with stable performance and reliable quality, and achieving good market feedback through continuous repurchases. In addition, the company accepts OEM and ODM orders.

Stability and Storage Conditions for Chemical Raw Materials

Overview of Chemical Raw Materials

Ningbo Guituo Trading Co., Ltd. provides a broad range of chemical raw materials including silicone additives, wetting agents, modified silicone oil, dimethyl silicone oil, surfactants, and defoamers. These materials are widely used in agriculture, daily chemicals, electronics, textiles, and other fields. Proper handling and storage are essential to maintain their stability, prevent degradation, and ensure consistent performance when applied in industrial processes.

Factors Affecting Chemical Stability

The stability of chemical raw materials is influenced by environmental factors such as temperature, humidity, light, and exposure to air or contaminants. Silicone-based products and surfactants can degrade or lose efficacy if stored under inappropriate conditions. Oxidation, hydrolysis, or other chemical reactions can occur, reducing their effectiveness in applications such as coatings, agrochemicals, and textile treatments.

Recommended Storage Temperatures

Most chemical raw materials should be stored in cool, dry environments away from direct sunlight. Silicone additives and dimethyl silicone oils from Ningbo Guituo Trading Co., Ltd. are stable at moderate temperatures but may experience viscosity changes if exposed to excessive heat or freezing conditions. Maintaining an optimal temperature range helps preserve their chemical properties and performance indicators.

Humidity and Moisture Control

Excessive moisture can adversely affect chemical raw materials, especially powders or water-sensitive liquids. Wetting agents, defoamers, and certain surfactants are prone to clumping, hydrolysis, or reduced activity if exposed to high humidity. Using sealed containers and desiccants where appropriate can prevent moisture-related issues and maintain long-term stability.

Light and UV Exposure

Some chemical compounds are sensitive to ultraviolet (UV) light or strong illumination. Prolonged exposure can trigger degradation, color changes, or loss of functional performance. Storage in opaque or UV-resistant containers, or in shaded areas, helps preserve the quality of chemical raw materials over time.

Packaging and Container Considerations

Ningbo Guituo Trading Co., Ltd. uses suitable packaging materials such as sealed plastic drums, metal containers, and high-density polyethylene bottles to protect chemical raw materials from contamination, air, and moisture. Proper labeling, tight closures, and secondary containment reduce the risk of chemical degradation and ensure safe handling in warehouses and production facilities.

Storage Recommendations for Common Chemical Raw Materials

| Type of Material | Optimal Storage Condition | Potential Risks if Improperly Stored |

|---|---|---|

| Silicone Additives | Cool, dry, away from sunlight, sealed containers | Viscosity changes, oxidation, reduced performance |

| Wetting Agents | Low humidity, moderate temperature, airtight packaging | Hydrolysis, clumping, loss of spreading efficiency |

| Modified Silicone Oil | Temperature-controlled environment, UV protection | Degradation, viscosity variation, reduced adhesion |

| Dimethyl Silicone Oil | Sealed container, away from high heat or freezing | Phase separation, reduced surface activity |

| Surfactants | Dry, ventilated storage, protected from contamination | Foaming changes, reduced solubility, chemical breakdown |

| Defoamers | Sealed, dry environment, stable temperature | Loss of defoaming efficiency, contamination |

Handling and Safety Practices

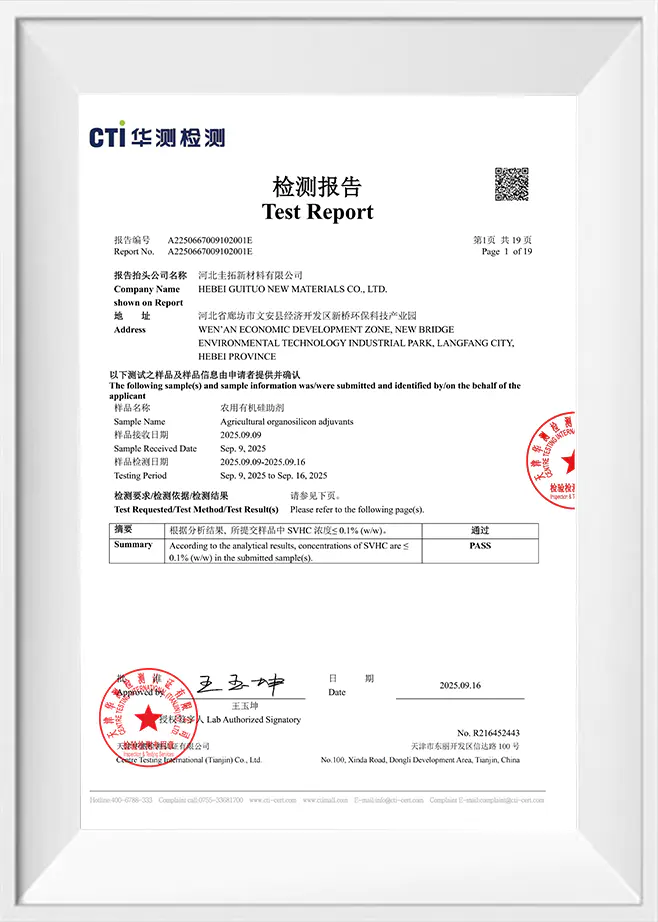

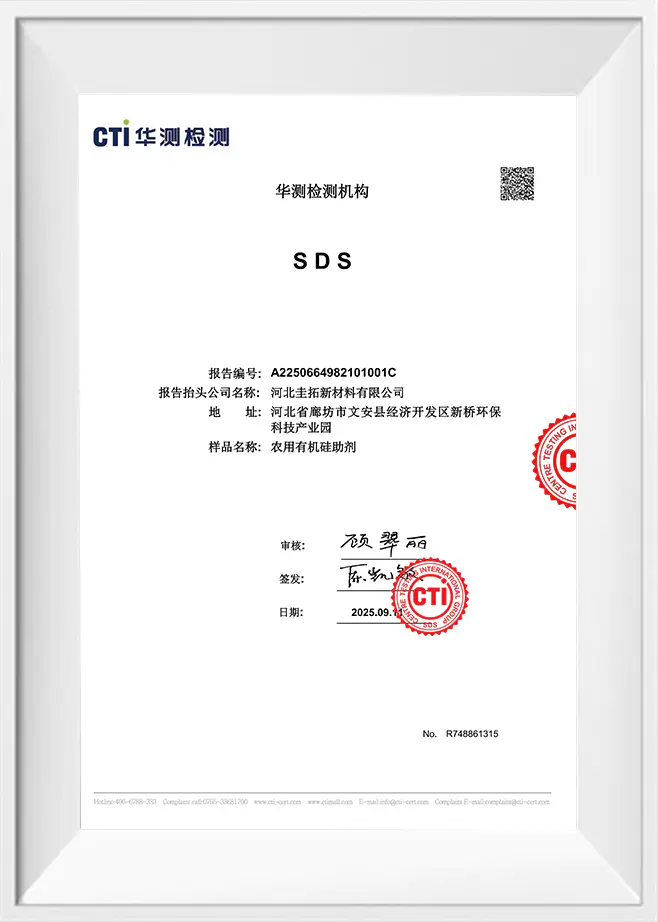

In addition to storage conditions, proper handling is essential to maintain chemical stability. Avoid cross-contamination between products, minimize exposure to air during dispensing, and follow safety data sheet (SDS) instructions for temperature, ventilation, and personal protective equipment (PPE). Ningbo Guituo Trading Co., Ltd. emphasizes these practices to ensure consistent performance and safety of its chemical raw materials.

Shelf Life and Inventory Management

Monitoring shelf life and managing inventory rotation are important to prevent the use of degraded chemicals. Implementing a first-in-first-out (FIFO) system ensures that older stock is used before newer material, maintaining effectiveness and reducing waste. Regular inspection of storage conditions and product integrity helps maintain long-term quality for silicone additives, wetting agents, and related chemical products.

FAQ

Q: What types of chemical raw materials does Ningbo Guituo Trading Co., Ltd. provide?

A: Ningbo Guituo Trading Co., Ltd. offers a wide range of chemical raw materials, including silicone additives, wetting agents, modified silicone oil, dimethyl silicone oil, surfactants, and defoamers. These materials are used across agriculture, daily chemicals, electronics, textiles, and other industries.

Q: How should chemical raw materials be stored to maintain stability?

A: Chemical raw materials should be stored in cool, dry, and well-ventilated areas, away from direct sunlight and sources of contamination. Using sealed containers and proper packaging helps prevent moisture absorption, oxidation, or other forms of degradation.

Q: Are Ningbo Guituo’s chemical raw materials suitable for industrial and agricultural applications?

A: Yes, the chemical raw materials provided by Ningbo Guituo Trading Co., Ltd. are designed for a wide range of applications. Agricultural silicone products, for example, are favored by leading domestic agrochemical enterprises for their performance in enhancing pesticide effectiveness.

Q: What safety precautions should be taken when handling chemical raw materials?

A: Handling chemical raw materials requires appropriate personal protective equipment, avoiding direct contact, minimizing exposure to air and moisture, and following the guidelines provided in the safety data sheets (SDS) to ensure safe use.

Q: How long can chemical raw materials be stored before use?

A: The shelf life of chemical raw materials depends on the specific product and storage conditions. Properly stored materials in sealed containers and controlled environments maintain stability for extended periods, though regular inspection is recommended.

Q: Can chemical raw materials from Ningbo Guituo be mixed with other chemicals?

A: Mixing should be done according to technical guidance and compatibility information. Certain silicone additives and surfactants may interact with other chemicals, so it is important to follow recommended formulations and handling procedures.

Q: How does Ningbo Guituo ensure the quality of its chemical raw materials?

A: The company uses advanced manufacturing equipment, precise CNC machining, and thorough production practices to maintain consistent quality. Continuous innovation and practical experience help improve performance and reliability across its chemical product range.

English

English  Français

Français  Português

Português