The Functional Mechanisms of 201 Methyl Silicone Oil in Lubrication, Mold Release, and Surface Modification

Overview of 201 Methyl Silicone Oil

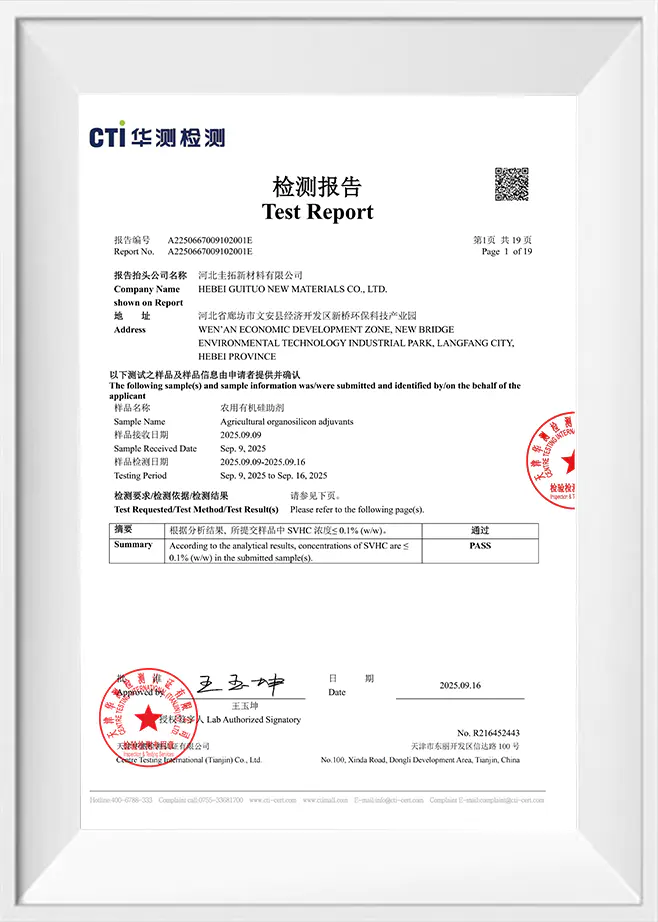

201 methyl silicone oil is a low-viscosity, linear dimethyl polysiloxane widely used for its lubricating, mold release, and surface modification properties. Its unique molecular structure, consisting of a flexible silicon-oxygen backbone with methyl groups, provides low surface energy, chemical stability, and thermal resistance. Hebei Guituo New Material Co., Ltd., with its extensive product matrix including dimethyl silicone oil, modified silicone oils, and surfactants, supplies 201 methyl silicone oil for a variety of applications across agriculture, daily chemicals, electronics, and textiles.

Mechanism of Lubrication

The lubrication function of 201 methyl silicone oil is based on the formation of a thin, uniform, and stable lubricating film on surfaces. The silicon-oxygen backbone enables free chain movement, which reduces friction between contacting surfaces. The methyl groups provide low surface energy, allowing smooth sliding and minimizing adhesion. In industrial applications such as textile processing, electronics assembly, and machinery operation, this lubrication mechanism helps reduce wear, improve processing efficiency, and extend equipment life. Hebei Guituo New Material Co., Ltd. leverages the lubricating properties of 201 methyl silicone oil to support industrial formulations that require controlled surface interaction.

Mold Release Mechanism

201 methyl silicone oil acts as a mold release agent by forming a thin, non-stick barrier between the mold surface and the material being processed. Its low surface energy prevents adhesion of resins, plastics, or rubber to the mold. The molecular mobility of the silicone oil ensures rapid spreading over the mold surface, creating uniform coverage without affecting the material properties of the molded product. In applications such as packaging, automotive parts, and daily chemical containers, mold release functionality facilitates efficient demolding and reduces defects. Hebei Guituo New Material Co., Ltd.’s silicone oils are optimized to provide consistent mold release performance in these diverse industrial contexts.

Surface Modification Mechanism

Surface modification with 201 methyl silicone oil involves the formation of a hydrophobic and chemically resistant layer on treated substrates. The methyl groups provide water repellency, while the flexible siloxane chains improve surface smoothness and reduce adhesion of contaminants. In agriculture, surface modification helps coatings and sprays spread uniformly on plant leaves, improving wetting and active ingredient deposition. In textiles, it enhances softness, antistatic properties, and water resistance. The ability to adjust viscosity and formulation compatibility allows Hebei Guituo New Material Co., Ltd. to supply silicone oil products tailored for specific surface modification requirements.

| Application Area |

Functional Mechanism |

Practical Outcome |

| Industrial lubrication |

Formation of thin lubricating film, low friction |

Reduced wear, improved processing efficiency |

| Mold release |

Non-stick barrier with low surface energy |

Efficient demolding, reduced defects |

| Agricultural coatings |

Hydrophobic surface layer formation |

Enhanced spreading and deposition of active ingredients |

| Textile finishing |

Surface smoothness and water repellency |

Improved softness, antistatic effect, and water resistance |

Viscosity and Its Effect on Performance

The viscosity of 201 methyl silicone oil influences its functional performance in lubrication, mold release, and surface modification. Lower viscosity oils spread more rapidly and provide better coverage for surface treatments, while higher viscosity oils maintain a more stable lubricating or protective film under mechanical stress. Hebei Guituo New Material Co., Ltd. offers 201 methyl silicone oils in various viscosity grades, allowing customers to select the most suitable product for their specific application needs.

Compatibility with Other Formulation Components

201 methyl silicone oil is generally compatible with surfactants, defoamers, and other silicone additives, making it suitable for multi-component formulations. In daily chemical products, combining it with wetting agents and emulsifiers allows improved spreading, smooth surface formation, and controlled foam behavior. In industrial coatings or agricultural sprays, proper formulation ensures uniform coverage and stable performance. Hebei Guituo New Material Co., Ltd. provides guidance on optimizing compatibility to maintain functional integrity across applications.

Temperature and Environmental Considerations

Temperature and environmental conditions can affect the performance of 201 methyl silicone oil. Its thermal stability allows it to retain lubricating and surface-modifying properties over a wide temperature range. However, extremely high temperatures may reduce viscosity, while low temperatures can increase flow resistance. For outdoor agricultural sprays or industrial processing, ensuring stable performance under variable conditions is essential. Hebei Guituo New Material Co., Ltd. evaluates products for temperature resilience to meet practical operational requirements.

Application-Specific Adjustments

Different applications require targeted adjustments in viscosity, concentration, and formulation composition. In mold release applications, higher concentrations may improve demolding efficiency, while in surface modification, the focus may be on achieving uniform hydrophobic coverage. Lubrication applications often require balancing flow behavior and film stability. Hebei Guituo New Material Co., Ltd. provides customized solutions, combining 201 methyl silicone oil with other additives to meet industry-specific requirements in agriculture, daily chemicals, electronics, and textiles.

FAQ

Q: How does 201 methyl silicone oil function as a lubricant?

A: 201 methyl silicone oil reduces friction between surfaces by forming a thin, uniform film. The molecular structure allows free chain movement, which minimizes adhesion and wear, supporting smoother operation in machinery, textile processing, and industrial equipment.

Q: Why is 201 methyl silicone oil effective in mold release applications?

A: Its low surface energy and molecular mobility allow it to form a non-stick barrier on mold surfaces. This prevents adhesion of resins, plastics, or rubber, facilitating efficient demolding and reducing surface defects in molded products.

Q: How does 201 methyl silicone oil contribute to surface modification?

A: It forms a hydrophobic, chemically resistant layer on treated surfaces. This enhances water repellency, smoothness, and reduces contamination. In agriculture, it improves spreading on plant surfaces, while in textiles, it enhances softness, antistatic properties, and water resistance.

Q: In which industries is 201 methyl silicone oil commonly used?

A: 201 methyl silicone oil is applied in agriculture, daily chemicals, electronics, and textile processing. Hebei Guituo New Material Co., Ltd. supplies this product as part of its diverse silicone oil portfolio to support functional performance in these sectors.

Q: How does viscosity affect the performance of 201 methyl silicone oil?

A: Viscosity influences spreading, film stability, and lubrication efficiency. Lower viscosity oils provide faster coverage and smoother spreading, while higher viscosity oils maintain thicker, more stable films for long-term protection and consistent lubrication.

Q: Is 201 methyl silicone oil compatible with other formulation components?

A: Yes, it generally works well with surfactants, defoamers, and other silicone additives. Proper formulation ensures stable performance, maintaining lubrication, mold release, and surface modification properties across multi-component systems.

English

English  Français

Français  Português

Português